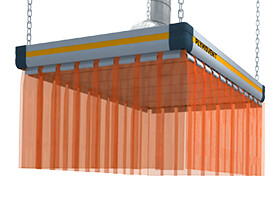

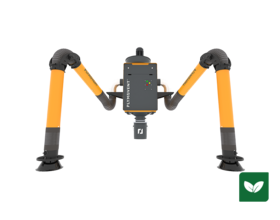

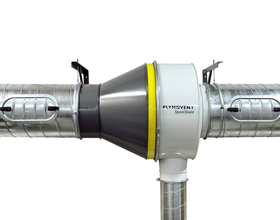

One of the key developments at EWA in welding and welding regulations is to protect the welder from hazardous fumes. This can be achieved by welding fume extraction equipment and solutions, which is one of the main areas of expertise of Plymovent.

Plymovent contributes to the EWA to make sure welders can count on “Clean air at work for everyone everywhere”, the mission of Plymovent.

The European Welding Association (EWA) is an industrial association of manufacturers of welding equipment and consumables as well as National associations from the welding industry from across Europe. Objectives of the EWA are amongst others to represent the interest of its industry in dealings with the governments of the EU countries, the Commission of the EU, other foreign countries and with trade organizations and all other bodies on matters relating to and affecting the industry. In addition the EWA works on revising existing and promoting new technical standards as may from time to time be necessary for trade throughout the EU and the rest of the world.