High-quality extraction and ventilation systems are an important part of a safe, healthy and productive factory environment. This is especially true when it comes to performing challenging, physically demanding, high-precision tasks, such as welding and burnishing.

Unfortunately, companies and workers sometimes still face their fair share of extraction or ventilation nuisances and problems on the work floor. These hindrances can negatively impact your company’s efficiency and productivity. In this article, we will take a quick look at some of these major problems, but we’ll also show you how Plymovent’s ControlPro Connect solves them.

Common problems with extraction and ventilation systems

Sometimes extraction systems in the factory don’t function as they should. The problem may be caused by incorrect settings or the need to replace a filter. The problem is that many companies simply don’t have the right oversight or necessary detection tools to quickly and easily identify the source of the issue.

Another issue that occurs on a regular basis is related to proper and timely maintenance.

Let’s say that an important part of your installation was in urgent need of replacement. Unfortunately, this was identified too late. The result is that several parts now have to be replaced. A costly affair and something that could have been prevented by an early warning. The maintenance manager must now examine each extraction system to establish whether maintenance needs to be carried out. This is a time-consuming and often confusing task.

Other common and regularly recurring problems with extraction systems are:

- Factories suffer from unforeseen failures of their extraction installations. As a result, all (welding) activities come to a temporary standstill, resulting in decreased productivity.

- Extraction systems work harder than they need to. This leads to increased wear and higher energy costs.

- Extraction systems are up and running outside working hours or during holidays. This leads to unnecessary costs and wear.

- Companies fail to set up a proper (predictive) maintenance plan because they don’t have the necessary data available.

- When an extraction system malfunctions, companies lack the knowledge to fix the problem in-house. Waiting for external support is often a costly affair.

- If a filter of the system where the extraction arm is connected to is replaced too late, or even replaced with a filter of inferior quality, it will negatively affect the quality of the air that is recirculated. (See blog “What can you expect from Plymovent filters”)

All of the aforementioned problems and situations have one common denominator: they negatively affect the productivity, efficiency and clarity of your factory processes.

ControlPro Connect

Luckily, we have designed a tool that can help you solve all of the problems that we addressed in the previous paragraph. Plymovent’s ControlPro Connect is a smart online platform that monitors and manages Plymovent extraction systems, such as the MDB and SCS. However, in order to do this, you have to equip the filter systems with a ControlPro operating system.

ControlPro Connect is a cloud-based tool that allows you to control extraction systems in an easy and efficient manner. The platform includes many functions that are aimed at monitoring and managing the extraction system based on adjustable thresholds, the type of exhaust fan and the corresponding fan speed. ControlPro Connect also allows you to:

- Adjust extraction systems to activities on the work floor with week timers, overtime timers and holiday timers.

- Group extraction systems and assign them to zones. You can even upload the floorplan of your factory, assign your zones and place your extraction systems on that map. Creating one overview in which you can see the status of all your filter systems.

- Generate notifications that inform you about problems or upcoming maintenance work.

How to get ControlPro Connect up and running

ControlPro Connect consists of a couple of essential components.

- The ControlPro is an intelligent platform that allows you to control extraction systems such as MDB PRO,

SCS PRO, MDB-Diluter PRO or SCS-Diluter PRO, but also the connected exhaust fans. All ControlPro systems ever build, can be connected to the online platform, provided they are equipped with the latest firmware update. - The i-Connect module establishes a safe connection between one or more ControlPros and Plymovent’s cloud solution. It serves as an important ‘hub’ (centre of a network) and allows you to connect seven extraction installations using ControlPro. Do you happen to need more connections? In that case, the i-Connect extension gives you the option to connect six extra ControlPros per unit.

- An internet connection. You can connect the i-Connect with the internet through an ethernet connection. It is also possible to use a cellular internet connection. For this you need a SIM card with a mobile data plan.

How safe is ControlPro Connect?

Safety is one of our top priorities. We can ensure that all data flows that go to and from the system are encrypted. When they arrive in the secure ControlPro Connect environment, data streams are decrypted. All information becomes transparent again and is neatly distributed over the correct pages and diagrams.

Available languages and information

The ControlPro Connect portal will be available in a wide range of languages. Starting with English as default language. These other languages will be introduced soon after the launch: Dutch, German, French, Spanish, Italian, Portuguese, Swedish, Polish, Hungarian and Czech.

ControlPro Connect makes the following types of information available and accessible:

- Five different graphs, which can be filtered per time unit (day, week, month or year). The different graphs focus on filter cleaning, energy consumption/energy savings, running hours (fan) , filter pressure, and fan frequency.

- These graphs offer historical data. This information allows you to recognise trends and make predictions.

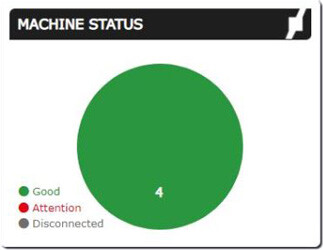

- Real time system information: system mode, filter, filter cleaning, ventilator.

- Overview of all active alerts (warnings/alarms). Also a complete logbook of all historic alerts per system.

The main benefits of ControlPro Connect

With ControlPro Connect, you can easily manage your extraction systems from anywhere via a secure environment. The system allows remote support and control of multiple systems by desktop, tablet and smartphone. You can also count on extensive advice from Plymovent experts to make your extraction systems function efficiently and optimally. Other benefits of ControlPro Connect are:

- Comprehensive real-time performance insights into all the extraction systems in your factory.

- Fast and direct support from your distributor or installer. Remote intervention is also possible.

- Receive alerts/notifications via email. This allows you to maintain control over your own equipment. Undertake action in a proactive manner.

- Draw up a preventive maintenance plan for your extraction systems. This ensures higher reliability and can prevent unforeseen downtime and loss of production.

- Smart tools with data from the past and insightful trends. Understand your systems through and through. “Guess less, know more” is our approach to extraction systems management.

More information

Would you like to know more about ControlPro Connect? Then don’t hesitate to contact us!

Just call +31 (0)72 7504 600, send an email to info@plymovent.com, or fill out the contact form and we will get back to you as soon as possible.