Effective removal of welding fumes & dust

Scania is a global company with sales and service organisations in more than 100 countries, with approximately 37,500 employees worldwide. Scania’s head office is located in Södertälje, Sweden. About 12,400 people work at production units, located in Europe and Latin America. Ferruform AB is one of the production units in Sweden, producing frame members and rear axle housings. Approximately 700 people work here.

The challenge

Ferruform AB (situated in Luleå) is one of Scania’s production units, based in Sweden. Scania is well-known for its (mining) trucks, buses and coaches. Besides, Scania produces engines for industrial and marine applications and power generation. At this location in Luleå work around 700 people. They make, among others, the metal bodies for the trucks. The steel frames are mainly produced by robotic welding machines. Occasionally manual welding takes place.

The welding activities at Scania generate a lot of welding fumes and dust. This pollution needed to be extracted effectively to be code compliant and to offer the employees of Scania a safe and healthy working environment.

Therefore, Plymovent created an engineered solution for the production unit in Luleå, Sweden.

The solution

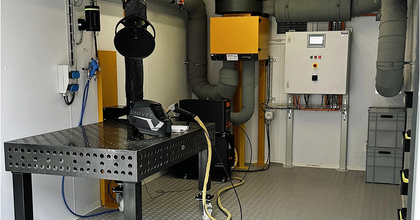

Various welding processes are taking place in this production unit of Scania, all at fixed workplaces. Plymovent developed an engineered solution and installed the following products:

■ Various extraction hoods to cover robotic installations.

■ Multiple arm systems with various extraction arms to remove welding fumes directly at the source.

■ OilShield limestone feeder units to prevent the filter cartridges of the central filter unit from clogging.

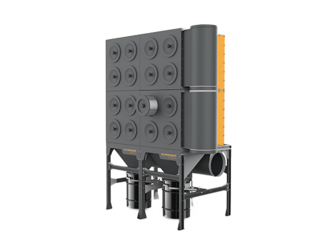

The extraction hoods, arms and limestone feeders are connected to ductwork. The ductwork is connected to a central filter system, the MultiDust® Bank (MDB). Plymovent opted for two MDB-40 units, meeting the required capacity.

In the automotive industry many welding applications involve oil e.g. to lubricate workpieces or machine tools. Oil is often the main reason that filter cartridges get clogged. To prevent filter cartridges from clogging by oil, Plymovent developed the OilShield. The OilShield feeds limestone into the ductwork, where it mixes with oils/oily fumes. The mixed limestone and oil become a dry matter, whereas it reaches the filter, falls down in the dustbin. Without the OilShield the filter cartridges were clogged constantly, which led to high maintenance and filter replacements costs.

Main benefits

- Effective removal of welding fumes and dust.

- Safer and healthier working environment, clean air at work.

- Code compliant.

- Less ventilation and heat costs, thanks to heat exchangers.

- Less filter cartridge replacement costs. Thanks to the effective limestone feeder, the filter’s lifespan is longer.

- Expansion of the existing welding fume extraction system is easy, prepared for future growth.

Testimonial

“We have been in contact with Plymovent for many years. They supplied high-quality extraction arms in the past. This time, we were looking for a large system solution to remove welding fumes and dust in general. Plymovent developed a system solution which met our requirements. Our production unit in Luleå needed to be code compliant.”

Quote by: Jan-Olov Waara, Project Manager of DynaMate AB (part of Scania)

Product list

Products

"Now, we are building 2 new production facilities nearby. We are already looking into the new welding fume extraction system together with Plymovent, of course tailored to our needs."

Gallery

View other case studies

We have installed thousands of systems worldwide, for many happy customers. What to know who they are?

View all case studies