MistEliminator units create a clean environment

AKS is a Japanese company that manufactures high-quality and durable balls from carbon steel and stainless steel through to ceramic and nylon. Founded in 1920 it has seven manufacturing sites and more than 1,500 employees worldwide. NSK-AKS Precision Ball Europe Ltd (England) was established in 1989 and taken over in 2005 by AKS.

Based in Peterlee (North Eastern England) they have a 6,860 m2 manufacturing site where they employ 126 employees.

The AKS brand ball is used in many applications, for not only automobiles, and bullet trains, but also NC machine tools, home electrical products, and recently, wind power generation systems.

The challenge

The manufacturing process of AKS includes the use of metalworking fluids (MWFs). These fluids are used to cool and lubricate the machining activity, prolonging the tool’s lifespan, removing the debris and protecting the surface of the workpieces. During machining, oil mist is produced by the interaction of the metalworking fluid with the moving parts.

The challenge set to Plymovent was: “Create a system which extracts oil mist generated at the source, to prevent it from creating a nuisance by entering the respiratory systems of the employees.” As oil mist can cause occupational respiratory illnesses, such as respiratory irritation, bronchitis, pneumonia, pneumonitis and extrinsic asthma. Oil mist can also cause contamination of machinery control systems, create slippery floors and increase housekeeping costs.

The solution

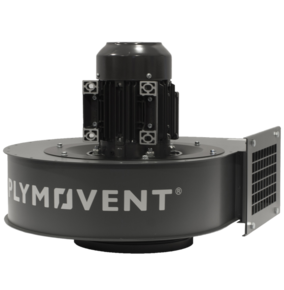

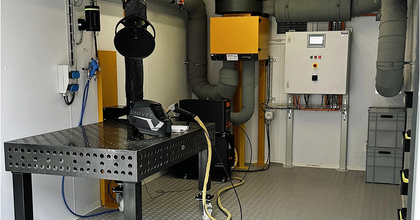

As AKS uses various machines throughout the workshop with metalworking fluids, Plymovent opted for MistEliminator units. The oil mist could be extracted directly from the source in every single area. The ideal solution!

MistEliminator unit ME-31 has one filter (HydroFilter) which can be used for all applications. The ME-31 unit adapts to the machine tool process, runs 24 hours a day and seven days a week. This was exactly what AKS were looking for, as the manufacturing site in Peterlee runs at high production levels.

Plymovent’s equipment led to a considerable improvement in air quality, visible and calculated, leading to a cleaner and safer working environment.

Now the average air quality is 0.8 mg/m3!

Main benefits

- Safer working environment, clean air at work.

- Improved indoor air quality.

- Reduced housekeeping costs.

- Maintenance-friendly, a differential pressure gauge indicates the status and need for filter replacement.

- 6 monthly servicing agreement, to check the filter wear.

Testimonial

“Since the installation of the Plymovent MistEliminator units, our consistent high level of weekly results (air quality) have improved and are as always well within the HSE regulations.”

Quote by: Mr. Ian Newton, Engineering Supervisor of AKS in Peterlee

Product list

"Plymovent is helping improve our good air quality to the next level."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studies