Saving valuable energy during the heating season

Leon Verbugt Speciaalbouw manufactures undercarriages for road transport, as well as the construction of special vehicles. In 2001, Leon Verbugt - at that time 28 years old - decided to put his experience and knowledge into practice by establishing his own company.

The challenge

MIG welding of aluminium produces a lot of welding fumes. Leon Verbugt uses approx. 4.5 tons of welding wire per year. Due to the large size of the workpieces and the relatively large distance between the welds, source extraction was impossible. Using a welding helmet with overpressure might have been sufficient protection for the welder, but the welding fumes would still pollute and accumulate throughout the workshop.

Ventilation gave no satisfactory result; it caused draught and a considerable heat loss in wintertime. Leon Verbugt tried to find a solution by building a movable hood over the workpiece, but that wasn’t a proper solution. Installing a push-pull system as a general filtration system was not possible because they often weld high vehicles and constructions, which would disturb the laminar airflow.

The solution

The hall in which most welding activities take place, measures 500 square metres and is 7 metres high. In this hall two Diluter systems have been installed, each consisting of a filter unit and an extraction fan.

The extracted air is filtered and blown out through the adjustable outlet nozzles on top of the fan. The outlet nozzles are positioned in such a way, that an optimum air circulation is created. An additional roof fan extracts a certain amount of air, which guarantees the supply of fresh air from outside the workshop.

As a result, the background concentration on the entire hall is kept below 1 mg/m3, while the maximum allowed level in the Netherlands is actually 3.5 mg/m3. The filter units contain a filter cartridge of 150 m2 with an automatic self-cleaning device.

Main benefits

- The Diluter system of Plymovent has a positive effect on the heating costs. Warm air rises; because of the air circulation this warm air is distributed all over the workshop, thus saving valuable energy during the heating season.

- Continuously clean indoor air.

- Control of welding fumes without ducting.

- Suitable for nearly all work locations.

Testimonial

"Without any filtration system, a blue layer of welding fumes would appear in no-time. With the Diluter systems of Plymovent - which are running all working hours - the air is kept clean continuously. Resulting in a clean and safer work environment for all of us."

Quote by: Peter Bennebroek, Welder at Verbugt Speciaalbouw

Product list

Products

"This solution is a great improvement compared to the past situation."

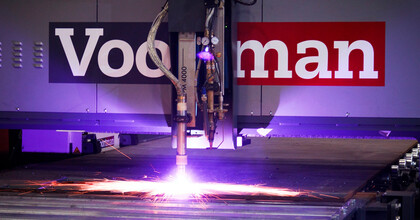

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases