From leisure activities to carrying the vast majority of all traded goods worldwide, ships have always played a significant role in our day-to-day lives. When shipbuilding technologies were introduced to new developments in the 19th century, welding replaced riveting, providing shipbuilders with major benefits including higher efficiency, smoother surfaces and lighter structures. Consequently, welding is now considered to be one of the most popular hot-work processes in the shipbuilding industry.

However, while welding has given the shipbuilding business important opportunities, welding fumes expose your workers to serious health risks if you do not take the appropriate action. As stated by the International Agency of Research on Cancer (IARC), long-term exposure to welding fumes can lead to multiple types of cancer. Taking the necessary precautions on your shipyard is therefore of the essence.

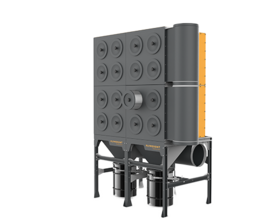

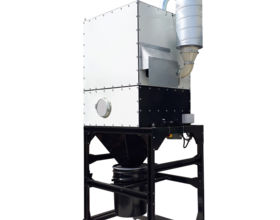

At Plymovent, we provide our clients with high-quality extraction and effective filtration systems that are designed to protect you and your workers from the start of construction until the day the ship is ready to begin its journey on the water. Being part of the shipbuilding industry means working in confined places but also incredibly big ones. No matter where you work, Plymovent can provide you with the proper solution.