Extraction hood XL removes welding fumes in training facility

Technum is a technical facility for courses and studies in the Netherlands. They have modern multimedia learning centres and high-tech engineering and practical classrooms for engineering, machine-building, steel construction, metal working and processing technology.

In the province Zealand, the prevocational primary and secondary education and universities all work together with the local companies and industry. In the coming years there will be a great demand for skilled technicians due to retiring employees and the resuming economy. Technum offers studies and courses for secondary education, adult education, re-entrants, business and industry.

The challenge

Technum, part of ROC Zeeland, has been designed by an architect. It has modern machinery, such as a CNC-driven water jet cutter and folding benches. All equipment must meet the high-quality standards and safety demands of the architect and institution.

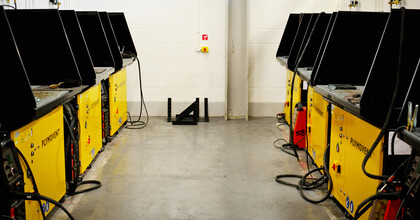

In Technum’s metal working place are an impressive number of youngsters and adults are trained during the day and in the evenings. The main activities are welding, cutting and grinding. The rule ‘safety comes first’ is strongly enforced. The students use the prescribed personal protection, which is compulsory. This includes welding helmets, which prevent the welding fumes of reaching the breathing zone of the welding students. For larger work pieces, the welding and cutting activities are performed on two large work benches. The only thing missing, was a high-quality solid extraction system to prevent accumulation of welding fumes throughout the open facility, protecting the participants against polluted air and remaining metals.

The solution

At first our downdraft tables were considered, but they were too small for the volume. Considering the size of the work pieces, source extraction wasn’t an option for this open training facility. The modular extraction hood of Plymovent, FlexHood, appeared to be the perfect solution. Both in the matter of functionality and design.

Thanks to the modular components, the extraction hood can be easily expanded and customised up to dimensions of max. 5.5 m x 5.5 m. When designing, a lot of efforts went into styling, lay-out and functionality. In the end the whole installation appeared to be producing little noise! The ideal solution for Technum!

The aluminium legs and profiles fit the architecture perfectly. Furthermore, the clear; transparent welding strips ensure that the teachers are able to keep an eye on the students, guaranteeing their safety.

Main benefits

- People working nearby are protected against welding fumes, sparks and spatters.

- Thanks to the low-noise exhaust bag the extraction hood generates little noise. This creates a pleasant working environment.

- The extraction hood doesn’t cover unnecessary floor surface thanks to its functional design.

- The transparent welding strips ensure a safe and survey able workplace.

- Modern design, this was the decisive element at Technum.

Testimonial

“We are very satisfied with the extraction hood of Plymovent. It has become a handsome and above all pleasant working environment, exceeding our expectations. Our participants clearly enjoy working underneath the hood for their welding and cutting activities. Since the installation of the extraction hood the interest in our work benches has increased considerably.”

Quote by: André Zuidijk, Manager Technum, ROC Zeeland

Accessories extraction hood

- 4 lighting fixtures

- Aluminium legs of 2.5 m incl. floor mounting plates

- Clear; transparent welding strips

"We are very satisfied with the extraction hood of Plymovent."

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases