Clean air in all welding cabins

Müller Martini Maschinen & Anlagen AG Hasle is the main supplier of formwork, constructions, and component assemblies for the Müller Martini group. Since the foundation in 1970 the enterprise continuously adapted to the developments and today produces on an area of approximately 19,000 m². Approximately 4,000 tons of steel sheet, stainless steel sheet, and aluminium sheet are processed each year in Hasle.

The challenge

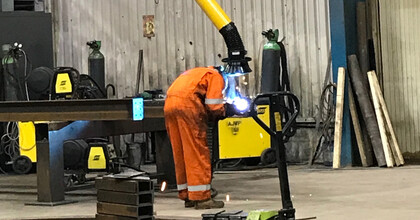

Welding work plays an important role in the work process. A total of nine welding cabins have been installed in a new part of the works. However, until now there was no welding fume extraction. Especially in winter, when the doors remained closed, there was a considerable amount of welding fumes in the halls.

At Müller Martini, it has been realized that the employees are the foundation for the success of an enterprise. They are qualified, motivated, act independently in the context of the agreed targets, and they feel themselves responsible for their actions. Thus it is intended to offer them the best possible work conditions.

The solution

Work on larger work pieces is done in the welding cabins. As they have to be repositioned regularly, the welding intensity is not very high. For continuous removal of the welding fumes, a suction-blowing system has been selected.

A U-shaped push-pull system has been installed in each of the two welding halls arranged one behind the other. With this, the dirty air is sucked off and filtered continuously.

The clean air permits maximum concentration onto the work to be done. In order to utilize the space in the halls as efficient as possible, the piping has been installed on one side between the shelves. For reasons of space, the filtration and ventilation installations also have been installed on specially constructed pedestals.

Main benefits

- Thus the air in the welding shop is always clean. The contamination does not reach other rooms, but is removed effectively.

- Because of automatic control and de dusting, the operating costs are relatively low.

Product list

"Clean air is our life, and thus we are content with this unit."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all case studies