Extraction arms remove dust effectively

Micron Bio-Systems, founded in 1993 in England, is an international leader in the biotechnology industry. Utilizing its scientific expertise in Microbiology, Enzymology, Biochemistry and Immunology, Micron develops product-based solutions for the Animal Husbandry, Companion Pet and Environmental markets. Micron’s products and programs are proven successful on commercial farms and at industrial applications. Micron’s integrated approach results in healthy productive animals and overall, a healthier environment.

The challenge

Micron Bio-Systems is situated in England. Micron makes among others feed supplements for the biotechnology industry. The manufacturing processes at Micron generate a lot of dust particles. Blending is a common process at Micron. They blend various particles which cause all kinds of dust in different sized particles. In England you need a dust extraction system to comply with the European standard FEMAS* for the integrity and safe delivery of animal feed materials and to meet the EU Feed Hygiene Regulation.

Therefore, Micron was looking for an effective dust control device with filters to ensure easy maintenance. Additionally, they were looking for a renewed and cost-effective solution to deal with the high volumes of dust created in the lab and workshop. The entire building is 1,525 m2 (incl. offices, lab and workshop). Plymovent was challenged to get the dust levels under control.

* FEMAS = Feed Materials Assurance Scheme.

The solution

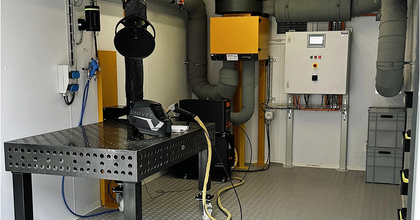

The Research and Development department of Micron uses the lab constantly creating successful products. They blend particles as part of their experimental process. This causes small dust particles. Plymovent’s MiniMan extraction arm is perfect in capturing various types of small dust and fume particles. It works apart from the existing systems, is easy to operate and fully flexible. The MiniMan arms provide to be efficient and versatile. Five MiniMan arms are installed in the laboratory.

The workshop itself has large blending machines producing a lot of dust all together. Plymovent’s SmartOne (S1) is a dry dust and smoke collector with a self-cleaning filter. The unit comes with a user-friendly filter monitoring system. The filter can be manually cleaned at any time. Clear and simple instructions on the filter housing, plus the large handle make changing the filter easy and convenient. The various blending machines in the workshop require more than one dust extraction device. Three KUA extraction arms were attached to the S1 dust collector to capture and remove the vast amount of dust. Various features make maneuvering the KUA arm a simple, one-movement operation. You can position the extraction arm exactly where you need it, when you need it. The S1 dust collector and the KUA arms suite the blending processes at Micron’s workshop perfectly!

Main benefits

- Not only the air inside is much cleaner than before, also the offices, lab and workshop (as less dust falls down).

- The dust extraction system creates a clean, safe and healthier work environment for Micron’s employees.

- Cost effective, significant reduction of cleaning costs.

- The extraction arms are easy to use and flexible.

- The S1 dust collector is maintenance-friendly. Replacing filter cartridges is easy.

- The extraction system meets the legal regulations.

Testimonial

“Plymovent installed a reliable and efficient solution. The extraction arms extract the vast amount of dust very effectively. Just what we were looking for!”

“If, in the future, we need to extend our business we will certainly contact Plymovent again. The provided solution turned out to be very reliable. Our employees find the extraction arms user-friendly. That is important, as they are the key-users.

Quote by: Lyndon Waite, Production Manager at Micron Bio-Systems

Product list

Products

- 5 x MiniMan (extraction arm)

- 3 x KUA (extraction arm)

- 1 x SmartOne (S1) dust collector

- This product is out of production, a newer and similar product is the MDB-Compact.

Application

- Blending

Service and maintenance

- 6 monthly service agreement

Find more information about the products here!

"Our employees find the extraction arms user-friendly. That is important, as they are the key-users."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases