Hessels is also going for the experience and expertise of Plymovent!

Hessels Zeefbanden based in Heiligerlee has been a leading company in the area of dewatering conveyors for more than 50 years. They can deliver dewatering conveyors in any imaginable size because they profile and cut their belts under their own management as the only ones in the Netherlands. In addition to their operations in the Netherlands, Hessels also operates in Belgium, Germany and France.

Hessels’ dewatering conveyors are made from the best materials using the most modern of production methods. They are mainly used in agriculture and horticulture, but also find their way to the fishing sector and industry in general. The products are sold to satisfied customers located throughout Europe. They also have buyers outside Europe including in New Zeeland, South Africa and Canada.

The challenge

Dewatering conveyors are produced solely under the company’s own management at Hessels Zeefbanden. Including the metal rods that are processed within them. These metal rods in different alloys are rolled at the ends after which they can be nailed on to the dewatering conveyor belts. The rods are rolled by heating the metal. Heating the metal produces much fume and dust emission, which is hazardous to staff. After rolling, hazardous substances are also produced. The rods are taken to what is commonly referred to as a “flash-off” location where they can flash off for a while longer.

The challenge was, therefore, to not just provide the customer with an extraction solution for the metalworking process, but also a suitable one for this post process.

The solution

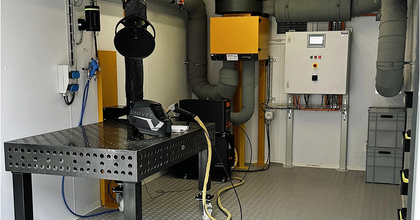

Plymovent studied all possible solutions in partnership with Hessels Zeefbanden because this is a very specific metalworking process. The different solutions that Plymovent can offer have been examined. They range from source extraction to spatial extraction and roof ventilation. After combining the ample experience and expertise of both Plymovent and Hessels Zeefbanden, they arrived at the conclusion and “encapsulating” the automatic metalworking machines and the flash-off locations would be the key to success.

The encapsulation was implemented in the shape of Plymovent’s extraction hoods of the “FlexHood” type with welding strips around every automatic metalworking machine and flash-off location. In addition, the choice was made for two workplaces to protect the employee directly at the source against the hazardous fume and du emission.

The choice was made consciously to equip every extraction hood separately with an automatic valve.

They are driven for each machine. This means that the automatic valve will open and the fan will increase in speed when the machine is switched on. This means that this process is extremely energy efficient!

In addition, the choice was made to provide the entire system with an automatic summer and winter control.

This means that hot air is discharged outside in the summer and that the inside air is recirculated in the winter. A hugely energy-efficient system has been developed because of this extensive automatic process that coincides with the activities and the simultaneity of the machines.

This highly technical solution that was created and elaborated by both parties in partnership shows that Plymovent’s welding fume extraction systems are not just suitable for the extraction of welding fumes, but that they can also be used for extracting substances released during other machining processes!

Main benefits

- A clean, safe and healthy working environment for all personnel.

- Conforming to the requirements laid down in Dutch law.

- Whenever possible, recirculation of clean and hot air takes place (the result: lower heating and ventilation costs).

Product list

Products

- 2 x T-Flex extractions arms

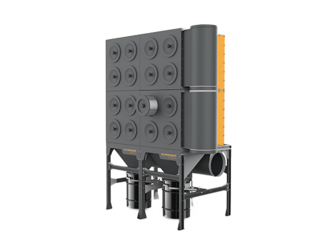

- 1 x MDB-24 filter unit

- 1 x CHB 30 18,5kW-4P ventilation box

- 1 x Full automatic frequency controller including vacuum sensors

- 2 x FlexHood 5x3m

- 2 x FlexHood 5,5x1,5m

- 1 x FlexHood 5x1,5m

- 1 x FlexHood 4x1,5m

- 1 x FlexHood 2,5x2m

- 1 x FlexHood 2x2m

"If we were asked to give a score to the partnership with Plymovent on a scale between 1 and 5, we would give it a 6!"

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases