Significant reduction of fume concentration

Case New Holland (CNH) operates under the wings of Fiat Industrial. As one of the most important manufacturers of agricultural and construction machines, CNH is active with an incredible 31,000 employees across the globe. The production branch in Zedelgem, established in 1906, develops and produces combine harvesters, forage harvesters and balers.

The challenge

In 2001, the policy makers at Case New Holland (CNH) in Zedelgem (Belgium) decided to take measures to limit the exposure of personnel to welding fumes. The high cost of heating fresh air from outside during winter months also seemed like a driving force for finding a solution to this problem. There is, however, no ready-made solution in place when it comes to companies such as CNH. Plymovent became a long-term partner for CNH, to reduce the welding fume concentrations systematically.

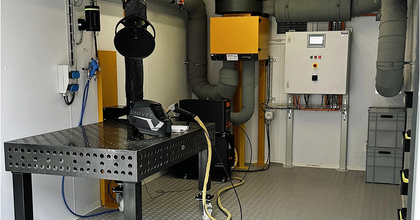

The production workshops in Zedelgem are subdivided into seven sections. For mechanical operations the company has various folding machines, laser cutting machines, presses, lathes and numerous welding robots and electric welding equipment. The intensive welding activities indisputably lead to massive welding fume concentrations.

The solution

“After the measurement of welding fume concentrations, we decided, in 2001, to intervene and initially installed two systems, including one Push-Pull system.”

Says Wim Vandenberghe, plant engineer at CNH Zedelgem. “During the following years we would deal with the critical zones systematically. If the spatial measurements indicate a measurement which exceeds the limit of 1 mg/m3, we are required to intervene. Even if we are not obligated to do so by law.

"The CNH standards are, after all, much stricter than those prescribed by law.”

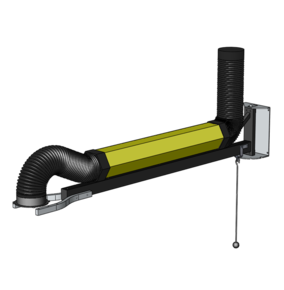

Long before ‘energy efficient’ became a buzz word, CNH’s internal ideology strived towards a process which is as ecological as possible. In the extraction of welding fumes, this approach also received connotation. The Push-Pull systems are therefore equipped with a filter unit, which purifies the warm, yet contaminated indoor air. “That certainly makes a huge difference when it comes to energy costs, especially in the winter months.”

Every year a GPT [APK] or General Periodic Test takes place. This test provides the user with a decisive answer concerning the proper functioning of the various extraction system components. This test is proof for the Labour Inspectorate that the company is active in the creation of a safe working environment, and in addition, also maintains this environment.

Main benefits

- Healthier working environment: - less exposure of personnel to harmful welding fumes. - less absence due to illness; previously natural ventilation took place in the winter months by opening the doors (fresh air).

- Safer working environment thanks to less concentration of welding fumes.

- 50% saving on ventilation costs. This results in a significant reduction of the high cost of heating fresh air.

- Annual check-up guarantees optimal system performance.

Testimonial

“In the past, workshop ventilation occurred by means of turning roof ventilator settings up or down. This method only succeeded in discharging the welding fumes in combination with a turbulent atmosphere, in other words, when the doors were open. This did, however, not seem like such a good idea, in view of heating costs and the health of employees.”

“All together, 14 systems have been installed over a time span of ten years. This involves source extraction and general filtration systems, such as Push-Pull systems. A clean working environment is a long-winded job, and that’s just how it is, but the results show, as per the figures.”

Quote by: Wim Vandenberghe, Plant Engineer at CNH Zedelgem.

Product list

Products

"Plymovent has proven to be an excellent partner in this multi-annual plan."

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases