Welding fume capture and filtration at Aceromas

Aceromas is a specialist in steel structure manufacturing, delivering projects throughout Chile and abroad. Their facility designs and builds high-voltage towers, tanks, manifolds, steel grating and more. Welding is a key step in this production chain — and it generates fumes containing fine metallic particles.

To protect their team and keep the workspace clean and safe, Aceromas asked our Chilean distributor Ambitec to design a solution that could capture fumes right at the source, without disrupting daily operations or limiting the flexibility welders need.

The Challenge

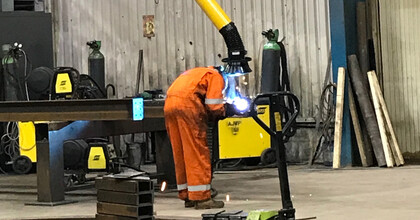

Welding takes place in a 21 × 5 metre area, where four welders work at the same time. Their tasks vary: welding on worktables, on trestles, at floor level and in 4G positions. This meant the extraction system had to cover a wide zone with very different accessibility conditions.

The challenge was to design a system that offered full reach and mobility across the workspace, captured fumes directly at the emission point, and filtered metallic dust efficiently — all without blocking movement or taking up valuable floor space.

The Solution

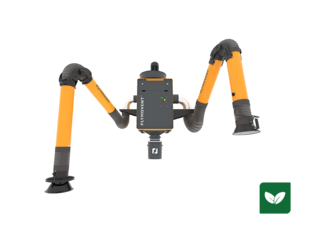

To meet these requirements, Ambitec proposed a system combining FlexMax-1530 extraction arms with compact WallPro filtration units from Plymovent.

The FlexMax-1530 arms, offering a reach of 4.5 metres, cover the entire welding area. They are built with aluminium ducts and flexible joint sections, making them light, stable and easy to handle. This design makes them ideal for welders working in different positions, while ensuring long-term durability.

The WallPro units complete the setup. These compact wall-mounted filters include a spark arrester, an M-Class filter with 20 m² of media, a 2.2 kW centrifugal fan with silencer, and an intelligent control panel. They offer 99.9% filtration efficiency for particles smaller than 2 microns and feature automatic filter cleaning once saturation is reached. Being wall-mounted, they free up floor space — and their operation is quiet, at just 67 dB(A).

Main Benefits

- Cleaner, healthier workspace – Fumes are captured directly at the source, keeping the air clear and reducing exposure to metallic particles.

- Full flexibility for welders – Long-reach FlexMax arms follow the work, whether welding on tables, trestles or at floor level.

- More floor space – WallPro units are mounted on the wall, keeping the work area open and uncluttered.

- High filtration efficiency – M-Class filter with automatic cleaning and 99.9% efficiency for fine particles (<2 microns).

- Quiet operation – The integrated silencer keeps noise low, improving overall comfort.

- Reliable, low-maintenance setup – Robust arm design and self-cleaning filter reduce downtime and extend service life.

Testimonial

Installation was quick and didn’t interfere with production. Operators noticed the improvement immediately:

“Visibility improves noticeably and there’s no welding smell anymore.”

With this solution, Aceromas improved air quality, raised safety standards and increased overall comfort and productivity for their team.

Product list

Products

"The improvement is clear right away. Visibility is much better, and there’s no welding smell anymore. It makes our daily work noticeably more comfortable."

Questions after reading the article?

We're happy to help!

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases