Mobile welding fume extractors ensure flexibility

Harsveld, situated in Velsen-Noord (NL), is for over 60 years a producer of pipe-works, plate constructions, tanks, pressure vessels and heat exchangers. The company supplies large technical companies both at home and abroad, such as Tata Steel, DSM and BAM. Harsveld is amongst others specialised in the processing of stainless, heat-proof and highly alloyed steel grades.

Harsveld is VCA** certified. One of the requirements for this is that its personnel must receive information 13 times every year regarding safety issues. This ensures that the knowledge of employees stays up-to-date. One of the subjects is ‘protection against welding fumes’. Joining these information sessions is mandatory for all employees.

The challenge

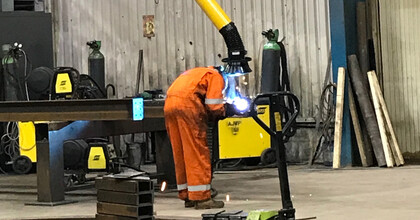

Harsveld Apparatenbouw BV employs approx. 50 staff members, of which 35 welders. All welders are certified and ‘all-round’ (MIG/MAG, TIG, stick welding, etc.) and continuously work with diverse, mostly high-grade metals.

The diversity of the welding operations results in welding fumes on many different locations. For certain assignments it’s not unusual that the lay-out of the entire manufacturing hall is completely converted. Thus not only the workplaces, but also the welding fumes extraction equipment demands flexibility.

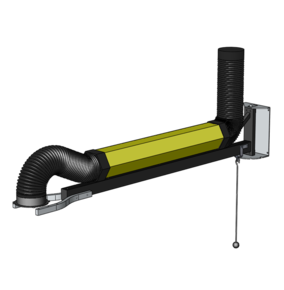

Plymovent’s mobile welding fumes extractor MFD with extraction arm UltraFlex-4 seems the logical choice. This combines flexibility, user-friendliness with a large control range.

The solution

Harsveld maintains a proactive policy of informing its employees of the dangers of welding fumes and the importance of a safe and healthy work environment. This also makes welders point out ‘unhealthy’ behaviour to each other, for example when extraction equipment is not correctly applied, endangering their own health.

Every welder owns a personal PPE package*. Half of the welders also has a personal mobile welding fume extractor. Especially the younger generation welders are well aware of their own health.

Harsveld has invested in 15 mobile welding fumes extractors, type MFD. The mobile units are all provided with the flexible extraction arm UltraFlex-4. This extraction arm has a range of 4 meters, used by the welders to perform their welding activities within a large range. Besides the mobile units, the company is also using a stationary system with three extraction arms, type UltraFlex-4 including extension cranes, type NEC-2, which results in a work area of 6 meters per welding place. A FAN-28 is connected to each extraction arm. The welding fumes are directed outside via the air cleaner SFE-25.

* PPE = personal protective equipment.

Main benefits

- A healthy work environment; thanks to professional extraction equipment of Plymovent.

- Mobile welding fumes extractors incl. UltraFlex-4 extraction arms ensure flexibility on the work floor.

- User-friendly; dirt indicator on the mobile unit indicates exactly when the filter needs replacement.

- Awareness, responsibility and safety; since 50% of welders has a personal mobile unit at their disposal, the welders are definitely aware of their own safety and maintain proper operation of the unit.

Testimonial

“The safety of our employees plays an important role in our company. The extraction equipment of Plymovent contributes significantly to this issue. We now purchase our extraction equipment from Plymovent partner Pomweld in Heerhugowaard; you simply call them and they arrange everything in no-time!”

Quote by: Aart Kramers, Manager Harsveld

Product list

Products

"The extraction equipment of Plymovent is a huge contributor to the health of our employees."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases