Mobile units offer Maximum flexibility

GP Groot was founded in 1917. Nowadays they employ about 750 people in the Netherlands. They have ceased opportunities in the waste management and recycling industry throughout the years. GP Groot focuses on three market segments: the collection & recycling of waste in general, renewable fuel & energy and infrastructure & engineering.

The challenge

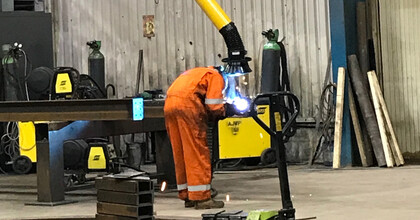

GP Groot has a workshop at the back of their offices in Heiloo, the Netherlands. In this workshop various welding processes take place on a daily basis. The metal workpieces that GP Groot has been maintaining vary from large ship containers, metal waste containers to metal parts of excavators.

GP Groot’s core business is waste management & recycling. They collect waste, recycle and generate new energy sources.

They needed a solution to extract and remove the welding fumes from their workshop to meet the Health & Safety Regulations on welding fume. They needed a flexible product as the welding activities and metal workpieces vary per project. Pomweld, an authorised dealer of Plymovent, opted for mobile filtration units.

The solution

It was clear that GP Groot needed a flexible solution to extract its welding fumes as GP Groot deals with all kinds of sizes of metal workpieces. Therefore fixed extraction arms –mounted to the wall or onto standards– were no option.

However, source extraction is the most effective way to remove welding fumes straight from the breathing zone of the welder.

That is why they opted for mobile filtration units. The extraction arms on top protect the welder directly, as the welding fumes are extracted straight away. This way the environment stays clean, as the welding fumes do not get a chance to accumulate throughout the workshop.

The mobile filtration unit is very flexible.

With the UltraFlex-4 extraction arm on top, it reaches up to 4 m. The hood of the arm can rotate 360 degrees. This means that you can position the unit, arm and hood exactly how you want, to ensure optimal extraction.

Additionally, the plug & play feature and easy operation make the unit user-friendly.

Main benefits

- Flexibility, you can use the mobile units anywhere you like in the workshop.

- The arms extract the welding fumes directly, protecting the welder from inhaling hazardous welding fumes.

- Source extraction –as the extraction of welding fumes via arms– keeps the working environment clean, as welding fumes do not get a chance to accumulate throughout the workshop.

- Overall: the welders are protected and the workshop stays clean.

Testimonial

“As welding became part of our business activities we needed a high-quality product that removes fumes from the air inside our workshop, to meet the Health & Safety Regulations. We have been in contact with Pomweld for a long time as they also supply our welding equipment.”

“Pomweld advised the mobile filtration units of Plymovent. I have to say that the flexibility of the mobile units are indeed very practical for our activities. The mobile unit is easy to move around and the extraction arm on top can be repositioned each time to ensure optimal extraction. We are very satisfied with the mobile units, they keep our workshop clean!”

Quote by: Kees van Ekris, GP Groot

"The mobile units extract the welding fumes effectively and the air inside the workshop stays clean."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases