A logical step to invest because of our workers

Antonino Dias Fernandes (ADF) is a fast-growing family company that was established in 1976. They have two production lines: various types of stoves and fireplaces on the one hand and large metal construction works, like public stairs and balconies of stainless steel, on the other. In the past years, they made substantial investments in production facilities, machinery and tools, labour conditions, environmental protection and education.

The quality control methods of ADF meet the highest standards. The annual production of stoves and fireplaces is approx. 1500 pieces, which they mainly sell through retailers. ADF is ISO 9001:2000 certified since 2003.

The challenge

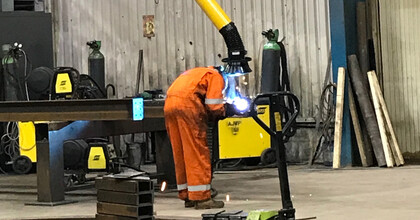

The entire production process of the stoves takes place in one area. It starts with the cutting and bending of the stainless-steel plates. Next steps are the cutting table and the welding. The annual consumption of welding wire is approx. 6000 kg, divided over 10 workplaces. Last steps are the surface treatment and painting of the final products.

Labour conditions are a very important issue at ADF. In order to protect the employees against welding fume and to offer them a pleasant working environment, they realized the necessity to keep the workshop free from welding fume.

The solution

The stoves are composed of relatively small parts. By applying extraction arms over the worktables, the welding fumes are removed directly from the source.

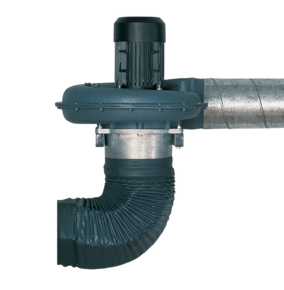

The extraction arms are connected to a stationary filter system type SFD with mechanical disposable filter cartridge. Due to its large filter surface of 50 m2, it is possible to mount two extraction arms, each with an individual fan, to one filter unit. The filtered air is re circulated back into the workshop.

Source extraction is the most efficient way of welding fume extraction. The 50 m2 highly efficient filter surface of the units ensure a large dust collection capacity, while a clogged filter indicator indicates when the filter cartridges need to be replaced. Antonino Dias Fernandes is very satisfied about the installation. It has appeared to be a very reliable system; the only parts that need replacement are the filter cartridges and sometimes a halogen lamp.

Main benefits

- Due to the large filter surface of the filters, this also appeared to be a cost-effective solution as far as the operational costs are concerned.

- The SFD filter units require no electricity.

- The working light integrated in the hood of the extraction arms guarantee a proper view on the work piece.

- All extraction arms are equipped with an automatic start/ stop sensor. This is a safeguard for the use of the system and it has a positive influence on the noise level and energy consumption.

Product list

Products

"We very much care about our workers’ health and well-being, so it was a logical step to invest in a welding fume extraction system."

Gallery

View other cases

We have made it our business to control welding fumes with source extraction, hoods or general ventilation and filtration systems

View all cases