Mini Rail Profile (MRP) is the preferred rail system for fire, ambulances and vehicle repair facilities

The Mini Rail Profile Fire (MRP-Fire) system is designed for fire and emergency systems to connect to a vehicle's tailpipe to capture and remove virtually 100% of exhaust emissions. MRP is fully automatic, from the fan activation to the automatic nozzle release from the exiting vehicle. It is easy to use with only a one-step connection to the system as the vehicle enters the facility.

The MRP is fully automatic, can accommodate up to two vehicles in tandem but can be engineered to accommodate more if need be.

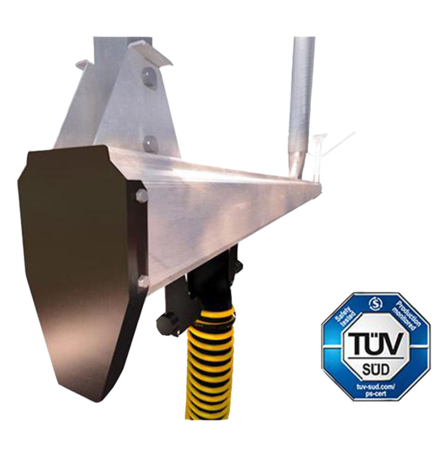

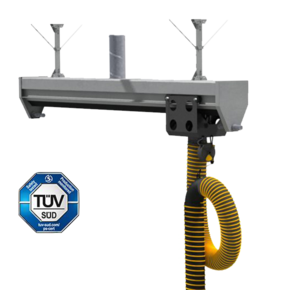

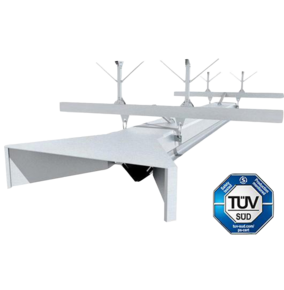

MRP features a square rail profile and an internal crab trolley that runs inside the rail.

Recommended for

VEX

- Military facilities

- Automobile plants

- Department of Transportation facilities

- Motorcycle/ATV garages

- Fleet service & repair bays

- Agricultural equipment facilities

- Bus depots

Fire & EMS

- Fire stations

- EMS stations

- ARFF stations

- Municipal fire stations

- Military fire stations

Features

- Perfect for smaller apparatus bays

- Provides an economic solution for long back-in bays

- Energy efficient system

- Easy to use

- Captures virtually 100% of exhaust emissions

- Fully automatic

- Standard design accommodates up to 2 vehicles in tandem

How The Mini Rail Profile (MRP) system works

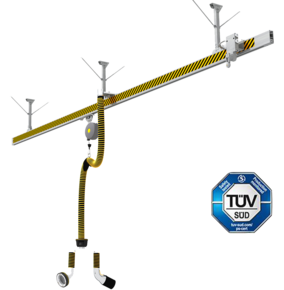

The Mini Rail Profile Fire (MRP-F) is an automatic, magnetic exhaust gas extraction system designed for the exhaust extraction of fire and rescue vehicles with low level, undercarriage exhaust tailpipes. The system is used to remove harmful vehicle exhaust emissions from the facility by capturing and removing the exhaust at the emission source, the tailpipe.

As the vehicle exits the facility, the trolley moves along to the end of the rail. The balancer locking cable secures that the Magnetic Grabber® is disconnected from the tailpipe outside the building.

Where the MRP is used

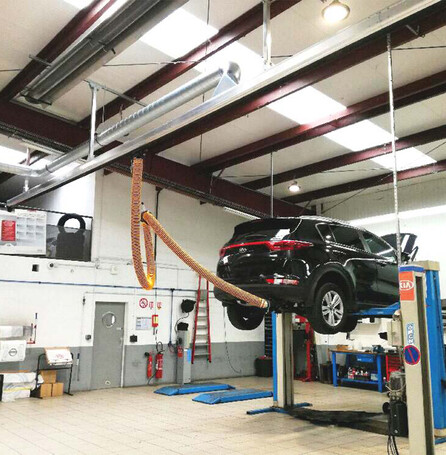

The rail is installed overhead along the service bays next to the fire apparatus and is connected to an exhaust fan. The internal crab is equipped with the proven concept of lower, -mid and upper hose combined with a nozzle and can be positioned at any service bay where extraction is needed.

Optimal and efficient extraction

The MRP can accommodate up to two vehicles in tandem but can be engineered to accommodate more if needed, thereby providing optimal extraction efficiency and an energy-efficient system. Exhaust emissions are vented to the outside through the rail system, typically through a single outlet.

TÜV SÜD certified product

The Mini Rail Profile (MRP) is available in 2 versions. The Mini Rail Profile Pneumatic (MRPP) and Mini Rail Profile Magnetic (MRPM). Both versions are certified by TÜV SÜD for safety and the production locations were monitored in Troisdorf (Germany) and Lamphun (Thailand).

A rail system alone, won't do much!

The Mini Rail Profile can be attached to a combination of the following products:

Exhaust hoses:

- High temperature hose: HT

- Standard temperature hose: ST

- Fabric composite hose up to 300ºC (572ºF): EF

- Vibration resistant hose: EG

- Highly crush resistant hose: EH

- Fabric composite hose up to 600ºC (1112ºF): ET

- Flame retardant and vibration resistant: EG2

- Light-weight, high-temperature, double ply exhaust hose: SNF2

- Synthetic composite fabric hose up to 300ºC (572ºF): EF2

Nozzles:

Balancer:

Optional

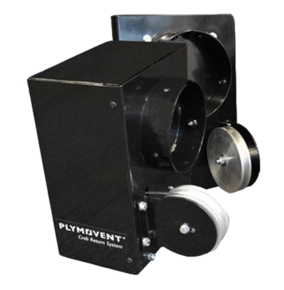

Fans:

Didn't find what you were looking for?

Our experts will be pleased to help you find a solution for your unique situation! Click here to get in touch with them.